Frezee Dry – Liyofilizasyon Makinesi

Soğutma Cihazları

Soğuk Hava Deposu Panelleri

Soğuk Hava Deposu Kapı Sistemleri

Soğuk Hava Deposu İçin Diğer Ekipmanlar

Atmosfer Kontrol Sistemleri

Patates ve Soğan Depolama Sistemleri

Muz Sarartma Sistemleri

GES Sistemleri

İthalat ve İhracat İşlemleri

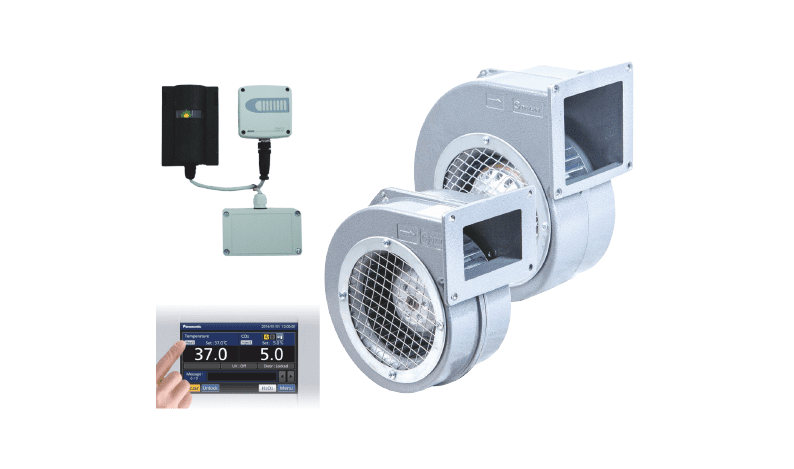

Another system in industrial cold storage is ventilation systems. These tanks contain normal atmospheric gases (78% nitrogen, 21% oxygen and 0.03% CO2).

Since fruits and vegetables are still living materials, they release various gases (ethylene, carbon dioxide, alpha-farnesene) and volatile compounds with respiration.

The accumulation of these gases and compounds in the warehouse causes physiological and pathological deterioration.

Therefore, the warehouses must be ventilated. There are various sensors in the ventilation process, and after these gases reach a certain level, the ventilation system is activated.

- Ethylene is a plant growth regulator that accelerates ripening and aging in vegetables and fruits.

- After ethylene is applied to the products, ethylene synthesis in the fruit is also encouraged and the fruits enter the ripening process rapidly.

- In climacteric products, once ethylene has been applied, there is no turning back and the product matures faster.

- However, in non-climacteric products, maturation is interrupted after the ethylene effect stops.

- It becomes susceptible to pathogen development in products that are sensitive to ethylene applications.

- It is also reported that ethylene triggers the damage caused by low temperature.

- Ventilation is the best way to remove ethylene gas from the tank.