Frezee Dry – Liyofilizasyon Makinesi

Soğutma Cihazları

Soğuk Hava Deposu Panelleri

Soğuk Hava Deposu Kapı Sistemleri

Soğuk Hava Deposu İçin Diğer Ekipmanlar

Atmosfer Kontrol Sistemleri

Patates ve Soğan Depolama Sistemleri

Muz Sarartma Sistemleri

GES Sistemleri

İthalat ve İhracat İşlemleri

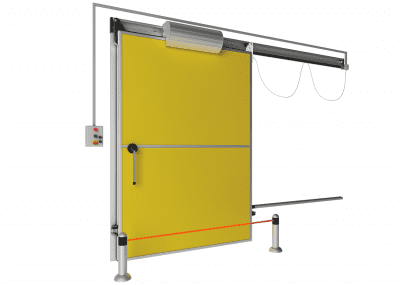

Industrial cold storage doors help to provide thermal insulation and heat balance. Sliding cold room doors are generally preferred in large warehouses because they can be produced in large sizes. In addition to standard production dimensions, it is also produced in special dimensions upon request. In addition, these doors are in constant contact with the exterior and are produced to prevent heat loss and sweating as they are constantly opened and closed.

Sliding door frames can be designed in two different types, optionally as PVC frame or aluminum frame. Sliding cold room doors can be used in any environment where thermal insulation is needed, especially in cold storage rooms.

Depending on the place where the sliding door will be made, it is designed to open to the right or to the left if desired. Replacing the specially produced resistors in the frame of the doors is quite simple. Since food products are usually stored in cold storage, hygiene is very important. For this reason, anti-bacterial materials are used in the production of sliding cold room doors.

Sliding cold room doors are available in 70 and 90mm thickness, and frozen storage room doors are available in 90, 120 and 150mm thickness wing options.

Sliding cold room door wings are produced as monoblock with 40-43 kg/m³ polyurethane foam filling.

There is a single row of gaskets on the wing of the sliding cold room doors, and a double row of gaskets on the frozen room doors. There is a single row of heating resistance in the gasket in the hinged frozen room doors.